Modelling and identification of mechanical behaviours based on heterogeneous in-plane biaxial tensile tests

The use of finite element simulations to optimise sheet metal forming processes requires a reliable and accurate description of the mechanical behaviour of the materials used, whatever the operating conditions (temperature, strain rate, complexity of deformation paths, etc.). The specific features linked to the identification of the elastoplastic behaviour of sheets include the characterisation of their anisotropic character and the accurate description of the material’s work hardening for large deformations. The heterogeneity of the strain field obtained on the surface of a cruciform specimen, during an in-plane biaxial tensile test, enriches the identification procedure and guarantees the integration of deformation states close to those observed during a forming stage. Biaxial tensile testing also has great potential for characterising highly anisotropic materials, such as composites. The most significant works in this research area are as follows:

- Identification of complex anisotropic plastic criteria for metal sheets from a single test, using spatial tracking of strain paths (from DIC method) ranging from uniaxial to equibiaxial stretching.

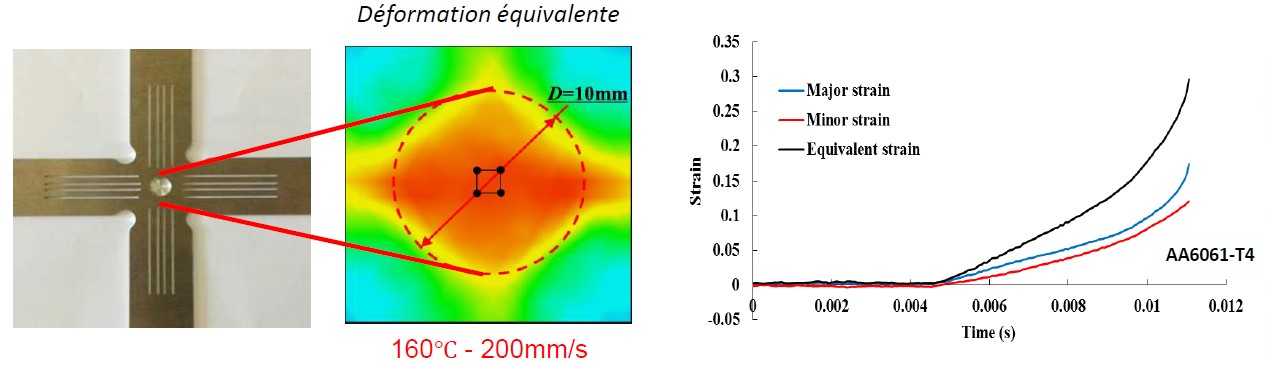

- Time monitoring of the evolution of principal strains in the central zone of a cruciform specimen for the identification of thermo-viscoplastic strain hardening laws by inverse analysis, for high strain levels.

- Characterisation of the mechanical behaviour of composite materials using a biaxial tensile test. Composites with a thermosetting matrix (characterisation of stresses at fracture for different biaxial ratios) and with a thermoplastic matrix (characterisation of the effect of temperature and strain rate for forming applications) are studied.

Study of the forming limits of metal sheets

The forming ability of metal sheets is classically evaluated by plotting Forming Limit Curves (FLC). The criterion used to plot these FLCs generally corresponds to the onset of localised necking in the sheet. In some cases, the onset of necking is delayed and the measurement of strain at fracture can be used to quantify the forming limit of the material. The main objective of this research area is to determine reliable FLCs that are well adapted to the real conditions under which forming processes are implemented (temperature, strain rate, complex deformation paths, etc.). The most significant works in this research area are as follows:

- Development of a conventional Marciniak-type device capable of establishing FLCs for different temperatures and strain rates. Deformations were determined by DIC method and limit deformations were identified by defining specific criteria. Using a complete experimental database, the aim was also to assess the relevance of predictive FLC models for the same operating conditions.

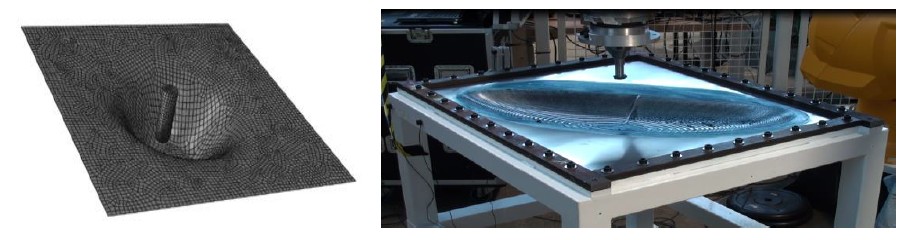

- Implementation of a new device for the characterisation of FLCs based on the use of a cruciform shape. The test is able to cover a wide range of strain states. The originality of the device also lies in its ability to apply linear and non-linear deformation paths.

- Study of the influence of the microstructure of a beta phase titanium alloy (Ti5553 and T21s) on its formability. Experimental characterisation of formability using a Marciniak-type device for different metallurgical states of the titanium alloy.

Simulation of innovative forming processes

The development of new grades of materials, coupled with the continuous improvement of production tools (flexibility, speed, product quality, etc.), leads to new innovative manufacturing processes. These new techniques are generally complex and require the control of various process parameters. Implementing a reliable predictive tool is a key step in ensuring the success of these processes.

- Implementation of a global material-process-machine approach for the simulation of the robotised incremental forming process. The elastic behaviour of the robot is integrated into the optimisation procedure in order to guarantee the dimensional accuracy of the formed parts.

- Mechanical characterisation of a titanium alloy under complex loading to predict forming forces during an incremental forming operation.

- Study of the effects of ultrasonic vibrations on a robotised incremental forming tool.